After installation and all wiring, a zero point adjustment (zero calibration) procedure should be performed. This procedure sets the base point corresponding to zero flow. Without actual flow there is a time delay between signal coils, this delay assumed as zero point. To perform this procedure, follow these steps:

Make sure that the fluid in the coriolis gas flow meter is completely still;

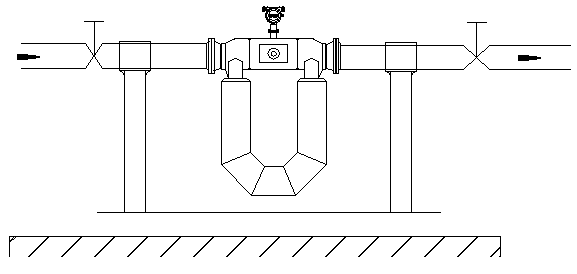

Common base

Figure.2.16 installation for zero adjustment

| CAUTION! |

| Place pipe supports as close to the process connection as possible

• Make sure pipe supports are securely clamped or attached to the process line • If multiple coriolis gas flow meters are installed in series or in parallel, piping to each meter must have separate supports. The coriolis gas flow meter should not share the same pipe supports • Do not install a coriolis flow meter in the highest part of the system. The lowest part of the system is required to keep the tubes full. |

| CAUTION! |

| ZeroPoint Flow calibration procedure should also be performed if the coriolis flow meter indicates any flow when there is no actual flow at the moment. |