Prior to installation, it is necessary:

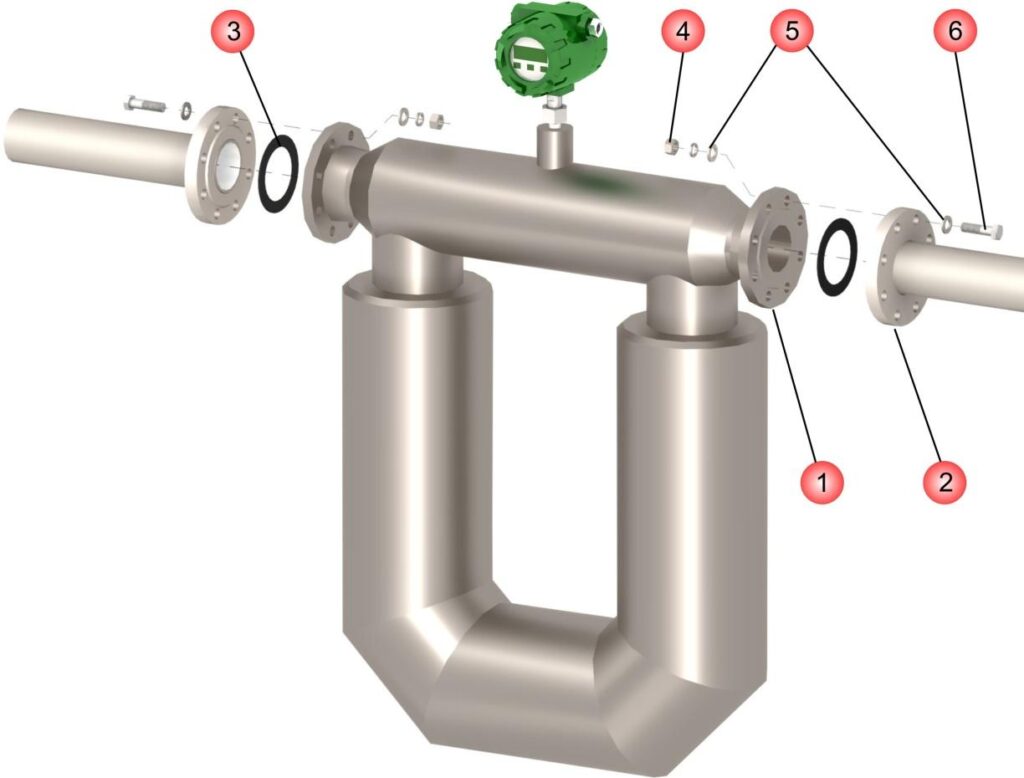

To install the coriolis mass flow controller in the pipeline do the following steps (see Figure 2.5):

To ensure proper installation of the Coriolis flow controller, it is crucial to avoid any bending or torsional stress on the joints. Additionally, it is important to ensure that there is no misalignment in the mating flange during installation. Taking these precautions will help to ensure optimal performance and longevity of the flow controller.

Figure 2.5 Installation of the coriolis flow controller in the pipeline

Table 2.3 – Notes for Figure 2.5

| Item No | Mounting part |

| 1 | flanges |

| 2 | Connection kit flanges |

| 3 | Gaskets |

| 4 | Nuts |

| 5 | Washers |

| 6 | Bolts (or stud bolts) |

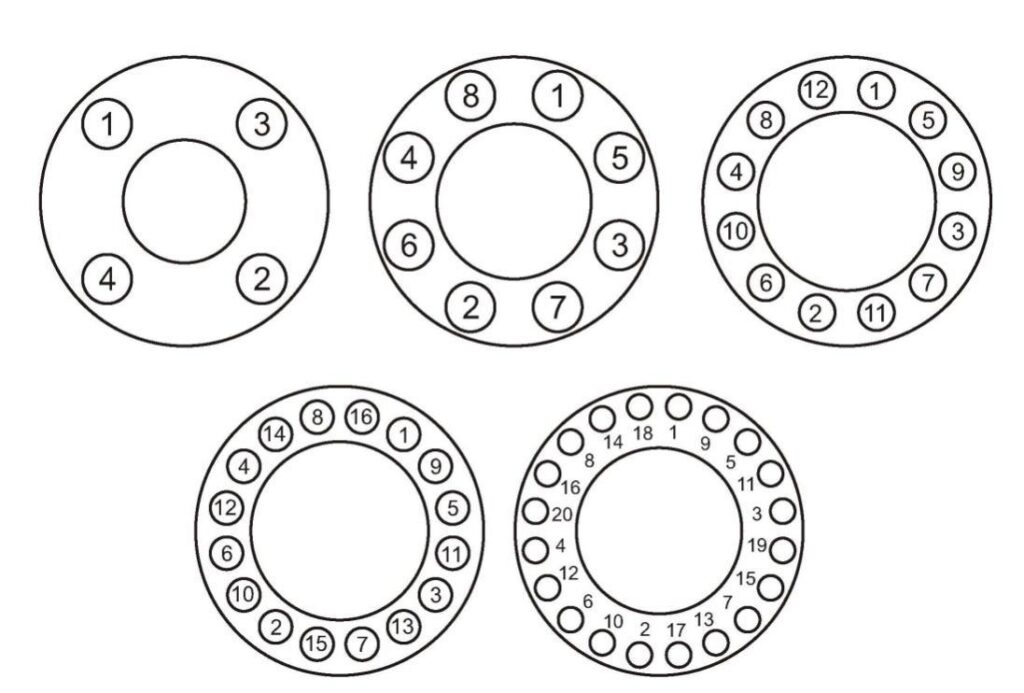

Figure 2.6 – The sequence of tightening the flange bolts

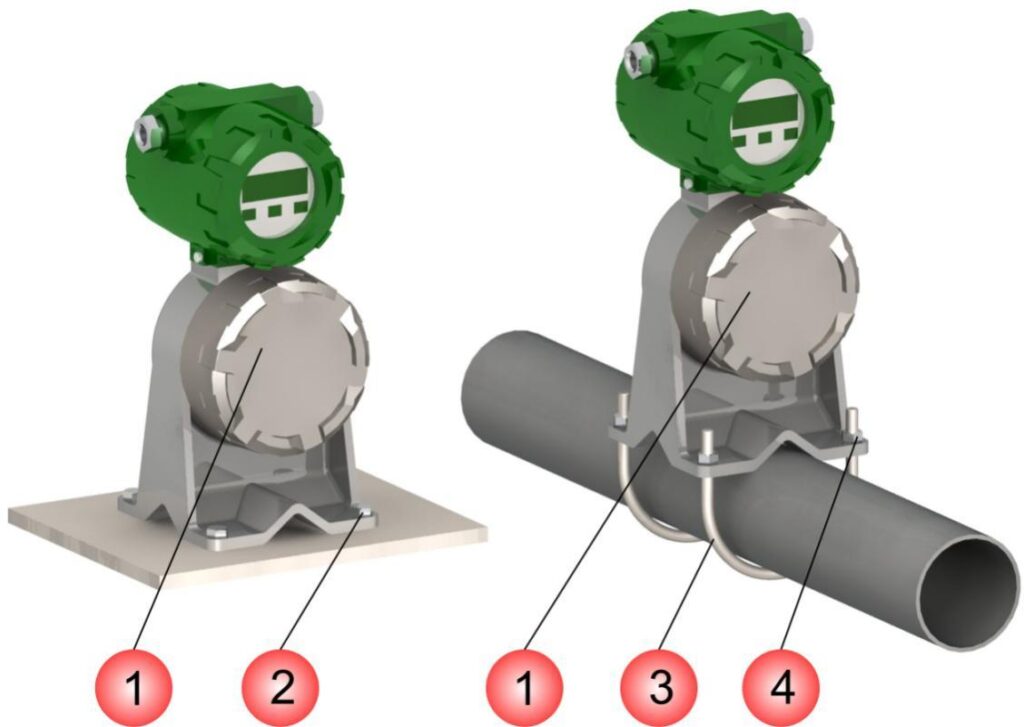

A potential rephrasing could be: “Figure 2.7 depicts a possible mounting configuration for the separate type of Coriolis flow controller’s transmitter. Brackets or clamps can be utilized to mount the transmitter onto a rack, pipe, or wall.

Figure 2.7 – Installation of remote transmitter type illustration

Table 2.4 – Notes for Figure 2.7

| Item # | Mounting part |

| 1 | Transmitter base |

| 2 | Bolts |

| 3 | Clamp |

| 4 | Nuts |

| CAUTION! |

| Do not install the transmitter with the cable entry oriented vertically upwards to prevent water ingress. Provide a Drip Loop. |