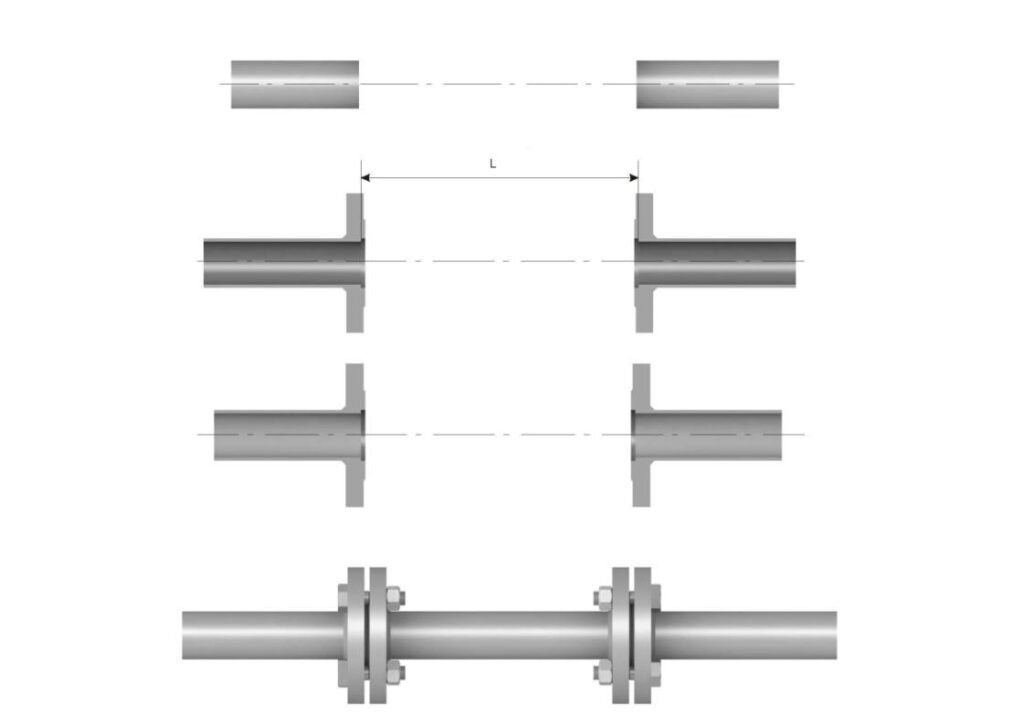

To prepare for the installation of the coriolis mass flow meter, it is necessary:

Linst = Lm + 2*Lg + 2*Lf, (2.1)

where Lm – coriolis mass flow controller length (see Appendix );

Lg – gasket thickness;

Lf – connection kit flange thickness minus thickness of flanges on the pipeline;

| CAUTION! |

| In the process of installation the coriolis gas flow meter may be used instead of the replacement mounting part only in the following cases:

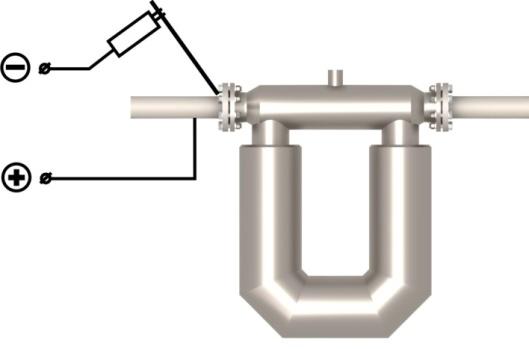

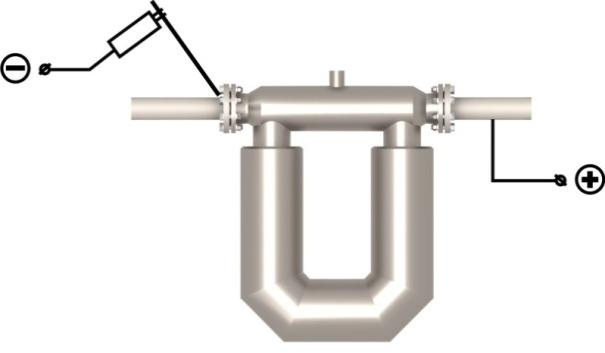

– installation is carried out using gas welding; – when installing using arc welding,the power source must connected in a way that prevents the welding current to run through the coriolis gas flow meter – see Figure 2.3. |

Right

Wrong

Figure 2.3 Connecting the power source for arc welding using the coriolis mass flow meter

To ensure accurate measurements, it’s crucial to follow the installation guidelines outlined in Figure 2.4. The length L of the installation should account for the total length of the coriolis mass flow meter as well as the thickness of the two gaskets used. This precise installation location will help optimize the performance of the equipment and maintain consistent measurements.

| CAUTION! |

| When using filters or gas separators, the length L should be sufficient for their installation. |