It is crucial to ensure the proper installation, operation, and maintenance of Coriolis gas flow meters by individuals who have undergone extensive training and possess a thorough understanding of the safety protocols for working with electrical equipment.

To prevent incidents of static electricity, it is imperative to comply with all requirements for protection while carrying out operations during calibration and use of Coriolis gas flow meters.

During installation and removal of the Coriolis mass flow meter from the pipeline, it is essential to ensure that there is no pressure in the pipeline, and the power supply is switched off. Electrical connections must also be made only when the power supply is switched off to guarantee safety.

Throughout the process of installation, commissioning, and maintenance, the following actions are strictly forbidden:

When conducting an installation, it is important to be aware of potential hazards, including:

To ensure safe operation and installation of Coriolis mass flow controllers with the “Ex” option, it is imperative to comply with the guidelines outlined in Chapter 7.3 of the Electrical Installations Code, as well as other regulations governing the usage of electrical equipment in explosive environments.

| CAUTION! |

| Installation and operation of the coriolis mass flow controller in conditions of pressure or temperature exceeding their maximum allowable values is prohibited.

Do not use the coriolis flow controller with the electronics cover opened, or without the chassis grounding. |

![]()

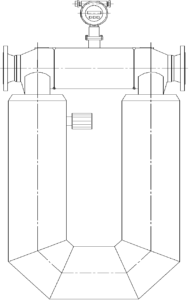

To prevent leakage of the gas filling the sensor’s outer shell, do not open the electronics cover 1.